If you are operating a high-speed steel wire rod mill, reducing cost and improving quality are key priorities. A crucial component is the “laying head pipe” which guides wire at high temperatures and speeds. To meet these demands, we offer the specially developed SAF 2507™ HLP pipe.

Addressing common challenges

SAF 2507™ HLP is a high-alloy, super-duplex pipe designed to offer enhanced durability and performance under extreme conditions. It helps meet the productivity and quality challenges of modern, high-speed wire production, overcoming challenges such as:

- Accerated pipe wear from higher rolling speed at extreme temperatures.

- Frequent replacements due inability to withstand heat, corrosion, and mechanical stress.

- Abrasion of the inner LHP surface causes unstable laying ring pattern.

- Poor and uneven wire rod quality due to inconsisten mechanical properties and tolerances

- High maintenance costs due to frequent replacements and increased downtime.

Main characteristics of SAF 2507™ LHP

- Very high mechanical strength

- Excellent wear resistance at high temperatures

Thermal expansion comparable to carbon steel

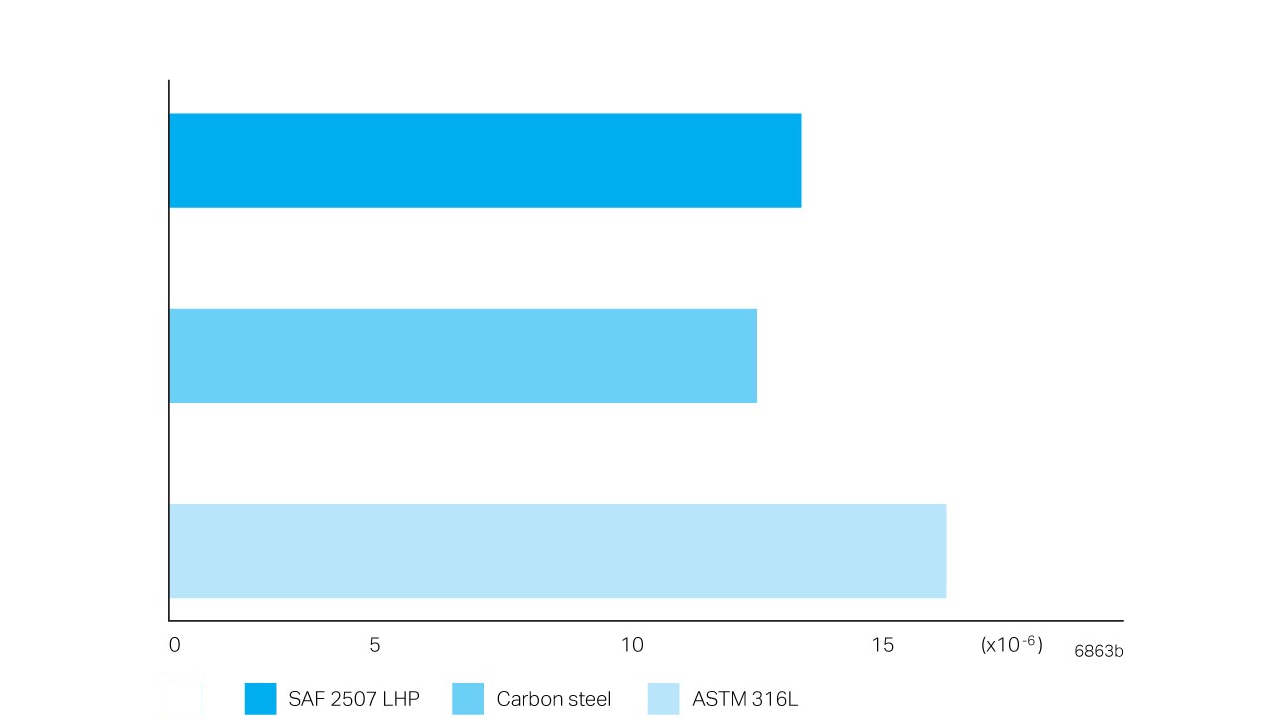

SAF™2507 LHP has a coefficient of thermal expansion closely matching that of carbon steel, allowing both materials to handle thermal stress at similar levels. This offers distinct design advantages over austenitic stainless steels, which is not as resilient at higher temperawhen, when when using equipment that utilizes both carbon steel and stainless steel components. The values given below represent average thermal expansion rates over specific temperature ranges.

Metric units x10-6/°C

| Temperature, °C | 30-100 | 30-200 | 30-300 | 30-400 |

| SAF™ 2507 LHP | 13.5 | 14.0 | 14.0 | 14.5 |

| Carbon steel | 12.5 | 13.0 | 13.5 | 14.0 |

| ASTM 316L | 16.5 | 17.0 | 17.5 | 18.0 |

Figure 1. Thermal expansion comparison between grades.

Modern mills

Historic development

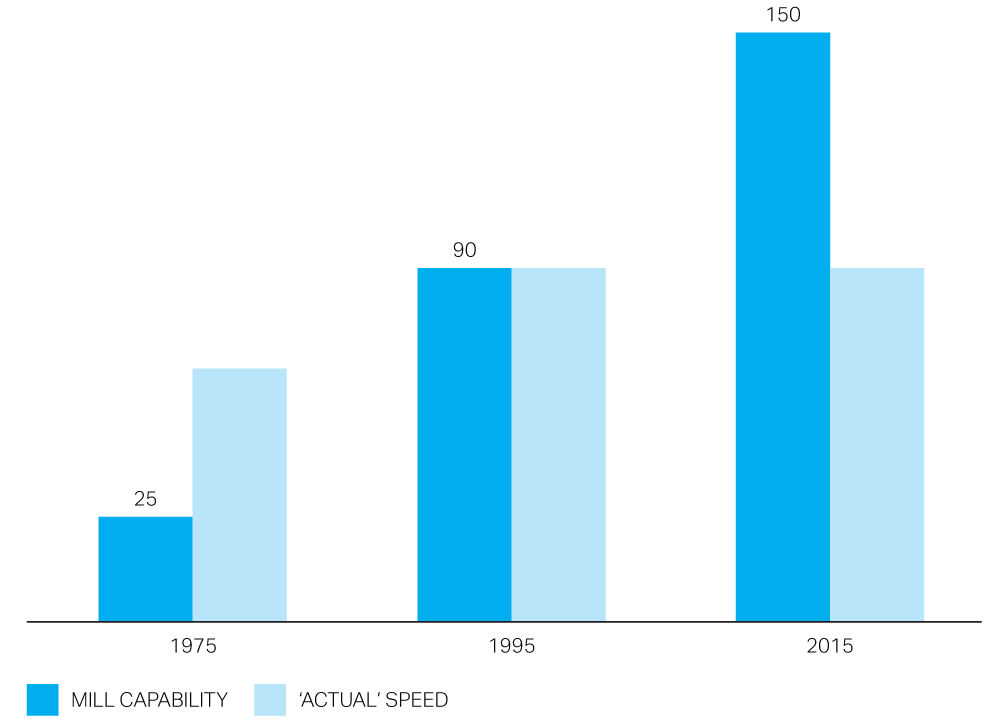

- Rolling rods of OD 5.5 mm at speeds up to 150 m/s (this requires LHP with ID ≈ 20 mm)

- LHP with reduced bore sized (ID ≈ 20 mm) should be used for small diameter products (OD = 4 ÷ 12 mm) for a more consistent pattern

Historic development of 5.5 mm wire rod rolling speed, mill capability (m/s)

Figure 2. Forced productivity, sub-optimization.